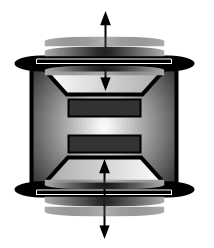

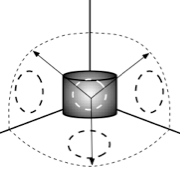

When the Blackbird & Raptor modules are stacked in a corner (as they were designed to be), the increase in output becomes even higher due to gain realized by the 4 boundaries presented by the 2 walls, the floor and the ceiling. The result is a higher output, lower power requirement system that reduces 2nd harmonic distortion while residing in a relatively small footprint.

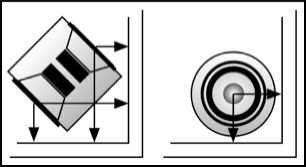

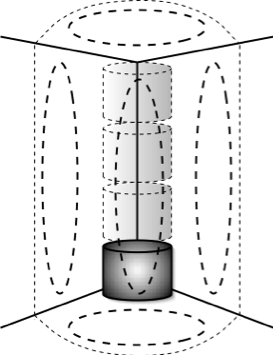

Boundary Gain is a phenomenon that occurs when a subwoofer is placed in the corner of a room. In this case, there will be three virtual images formed from the original drivers in the subwoofer, one on the floor and one each on the adjacent walls. This concentration of the original source plus the three additional “virtual” sources combines to create a new single source of considerably improved efficiency. Depending on the integrity of the walls and floor, the increase can be anywhere from 4 to 64 times! When a stack is employed, the three virtual sources become 4 by addition of the ceiling as a reflective surface. Not only will this increase efficiency, it has the effect of eliminating the typical standing wave that occurs at twice the distance from floor to ceiling, which is around 70 Hz in a room with a typical 8 feet ceiling height. Since 70 Hz is right in the middle of the typical 80 Hz crossover used in Home Theater, the benefits of stacking are certainly worth consideration.

Blackbird’s front accent strip is made from solid American walnut, finished with semi-gloss urethane to protect it and to bring out the ageless beauty of the color and grain, each piece being one-of-a-kind and adding the perfect finishing touch. An all-new curved front panel covered with hole punch pleather has been designed for the latest Raptor and is being used exclusively to achieve and all-black look that will blend with just about any decor.

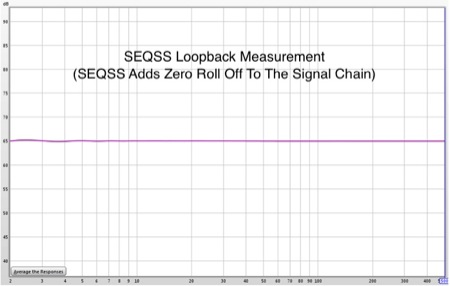

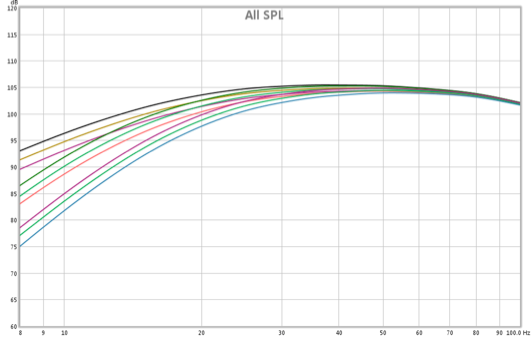

9 preset curves from (+0/-3dB)16-200 Hz to (+0/-3dB) 32-120 Hz

Boundary gain of +18dB (64 times!) less the sound transmission losses of the boundary due to the boundary construction method.

vs

24dB ((256 times!) added potential boundary gain, less the floor-to-ceiling standing wave non-linearity

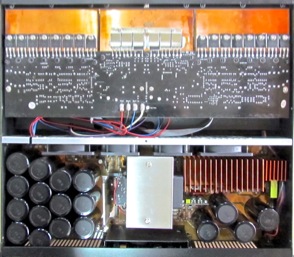

The surround is an all-new hybrid half roll/tall profile made from an all-new rubber compound and is designed to allow full linear excursion without reaching its maximum potential. We decided, after testing every available material and profile, to design the surround from scratch and specifically for our systems. To get the equivalent excursion from a typical half roll surround, we would have had to sacrifice cone surface area, yet we found that the typical tall-narrow surround traded cone area for linear performance. Experimentation culminated in the best combination of profile, material, thickness, cone area and performance.

Dual Nomex spiders were designed and spaced to prevent rocking during maximum throw and a quick return to zero after signal input ceases, just what a spider is meant to provide.

The cone is a rather conventional non-pressed paper overlaid with an all-new coating. It’s light yet stiff enough to withstand the violent excursions required for state-of-the-art low frequency reproduction to single digit Hertz.

We designed an all-new 6 spoke aluminum basket that’s light yet strong and the new motor design includes three huge aluminum Faraday rings to smooth the free air response and to reduce non-linear response in the crossover region.

A single Raptor module yields up to 9 liters of displacement to Blackbirds 6.5. These are not arbitrary quantities. Conventional wisdom generally dictates that, when designing a sealed subwoofer, longer throw, therefore more displacement, is automatically better. Our philosophy is instead to hit the target cleanly with no wasted costs, effort or raw materials. With available technology, it isn’t difficult to to build an overkill driver. The challenge is to design a driver that performs up to the requirements of the system it was designed for, using just enough raw materials, honing the assembly process to a standard of quality that will keep them in the system and working and out of the landfill.